It took Ford over 100 Years to figure out how to build a unique F150 with 30,000+ parts every 48 seconds.

How does your production process compare?

|

Are you tired of missing delivery dates because your process is too slow? Is it frustrating that you lost to the competition because your price was too high? How many non value added people do you pay to fiddle around with computers and spreadsheets to get you order and production data? |

Are you pissed off because missing parts are holding up production? Anxious about poor inventory management consuming too much capital while restricting sales or creating excess carrying costs? Do these bottlenecks prevent you from reaching new customers and sales? |

End the Chaos

It's time for a fresh start and a return to simplicity.

Speed is Key to Growth and Customers

|

Envision the financial landscape reshaped by optimizing your product production speed. Picture the potential of doubling sales volume without a significant increase in capital expenditure, achieved by significantly reducing the time it takes to bring your products to market. In today's business environment, characterized by its rapid pace, the importance of speed cannot be overstated. The ability to produce goods quickly is not merely a competitive advantage; it stands as the linchpin differentiating success from failure in customer relationships. Make this happen by strategically streamlining your production processes, starting with a focused data model from receiving to shipping for a seamless and accelerated workflow.

|

Fix Your Production Bottlenecks

|

Production bottlenecks frequently emerge due to communication gaps, insufficient tracking, bad data, poor practice and inventory problems. (The list can go on) These challenges lead to disaster and headache. Addressing and fixing bottlenecks requires accurate tracking data of the production process. Gathering this data in the past has usually been too hard and cumbersome and that is why it is neglected or someone attempts it with a spreadsheet. A simple method must be found to collect accurate data and peer into the process to find and fix bottlenecks. If we are able to do this, how do we do it and what will we find?

|

Revealing Hidden Havoc: Confronting Wasted Time and Money

|

This process is going to open the door to all the problems and bottlenecks that exist today. We are going to expose all the bad habits and poor practices that flush time and cash down the drain. You will be shocked when you see how much time is wasted as product and jobs wait for value added resources. Furthermore you will now realize that every moment of time wasted is forever lost.

|

Unlocking Truths: QR Scans for Smarter Production

|

Using simple QR scans we are going to record each step of the production process. This data will pull back the curtains of confusion and reveal the truth. This actionable data will allow you to make rational decisions to speed production. The good news is that we do not need to change or disrupt your current systems. The 2X discovery process stands alone. The bad news is you may not like what you find. This journey of discovery will be eye opening and frustrating at the same time when you realize how much has been wasted

|

F150 Drives Cutting Edge Productions Speeds

|

To speed up your production process, we have an innovative solution inspired by our collaboration with Ford's F150 Truck program. We designed and built ILVS software (In Line Vehicle Sequencing) that reduced time for suppliers to deliver the 30,000+ parts to build an F150 every 48 seconds.

We will use what we learned and apply that knowledge to your production process. We believe the data will show us that you have the potential to cut your production time in half. |

Build Products Twice as Fast with MonitorZ

|

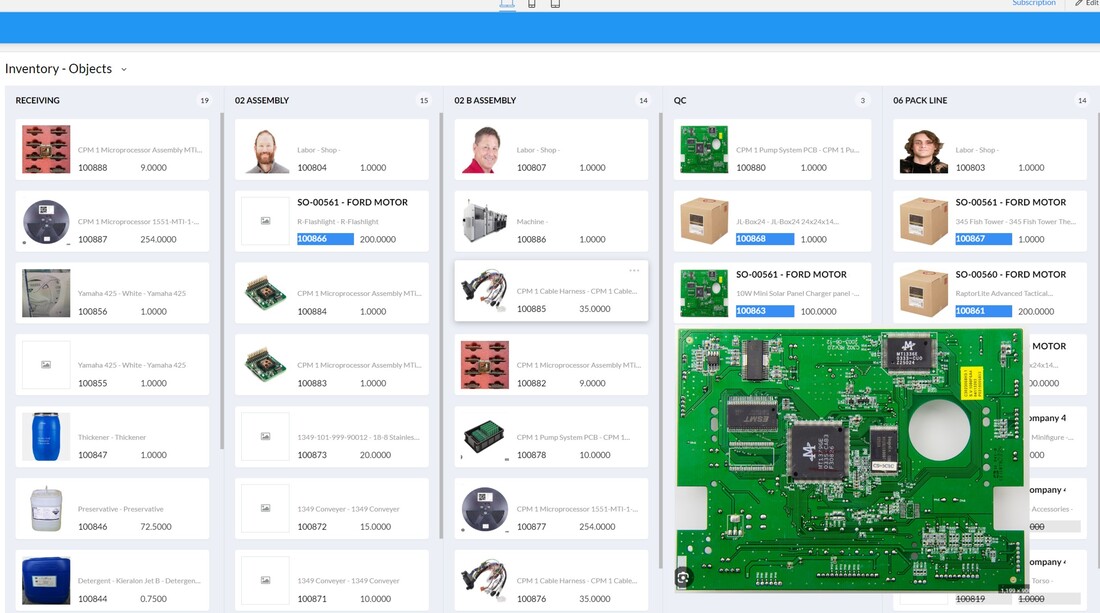

Now that we have a process to collect the data as production flows we can now start to see the the reality of how long it actually takes to build the product and all the bottlenecks in the way that keep it flowing smoothly.

|

See Everything and Everyone

|

Imagine trying to keep a patient healthy without accurate data on their vital signs. Your manufacturing process is no different. Without real-time data from the shop floor, it's impossible to ensure the health of your business. Most ERP systems are designed for the office, not the factory floor, leaving you with incomplete information and causing chaos. MonitorZ was built to eliminate this problem. By collecting data directly from the manufacturing work centers, MonitorZ ensures that you always have the accurate data you need to make informed decisions and drive profits.

|

|

See your machines, people, Inventory and more on the shop floor. Most importantly, see exactly where all your Customer Orders are at all times Keep precise track of Production and Customer Orders as they progress through your work centers. See the difference between value added time and idle time. Production waiting on the floor for the next step is wasted opportunity. Take action before problems spin out of control so you can keep your customer promises.

With the ability to see delays and idle time, it now becomes possible to make improvements to increase your output. |

The Results and Benefits

Increase Throughput will get your Products completed Faster

Decrease operational expense will Increase Profits

Decrease Inventory levels will provide more Working Capital

Increase Inventory Turns will Increase R.O.I. on Working Capital

Eliminate Waste will Free up time and Working Capital

Reduce headcount will Reduce Expense/Add Capacity

Increase Capacity allows you to Sell more Products

Reduce Lead times provides more Opportunity to Increase Sales

Peace of Mind that your Performance is on the Rise.

Decrease operational expense will Increase Profits

Decrease Inventory levels will provide more Working Capital

Increase Inventory Turns will Increase R.O.I. on Working Capital

Eliminate Waste will Free up time and Working Capital

Reduce headcount will Reduce Expense/Add Capacity

Increase Capacity allows you to Sell more Products

Reduce Lead times provides more Opportunity to Increase Sales

Peace of Mind that your Performance is on the Rise.

Testimonials

|

"An excellent leader with far-reaching vision that accounted for the success we all experienced" - Peter Pfaff Ford Motor Company "Exceeded our expectations and accelerated our growth." - Steve Markivich Guardian Industries (a division of Koch Industries) |

"Visionary empowerment of monitoring key business initiatives." - Dean Lampere Borg Warner a Fortune 500 manufacturer. "You guys utilize our software better than we do. What you have built is impressive." - Sridhar Vembu CEO Zoho Corp. |

Accelerating Success to Drive Your Growth

Revolutionize your success journey with F150-inspired innovation, speed as our drive, and decades of proven excellence. Elevate your performance now and redefine what's possible for unparalleled growth

In summary, Ford invested over a century in mastering the assembly of a unique truck with 30,000+ parts every 48 seconds. Now, connect with us to discover how you can leverage this knowledge to supercharge your production and boost your sales.

In summary, Ford invested over a century in mastering the assembly of a unique truck with 30,000+ parts every 48 seconds. Now, connect with us to discover how you can leverage this knowledge to supercharge your production and boost your sales.