|

Are you tired of traditional ERP manufacturing methods that drain your time and expense? Do these bottlenecks prevent you from reaching new customers and revenue? |

Are you running with disconnected systems and bureaucratic processes that are frustrating? |

The Challenges of Traditional Manufacturing ERP

Manufacturing is a demanding process that often leads to endless problems and headaches. The problem is the system. Traditional ERP is based on archaic data models and is flexible as a tombstone. They force you to do things different from the way you build and deliver products to your customers. That is why office people resort to spreadsheets to get around the cumbersome lack of flexibility. As you grow the bottlenecks grow with it until they become untenable and prohibits your growth and potential.

The system causes inventory shortages, late shipments, production delays and the list goes on. You can see in your head how it should be done but you are stuck with what you got and it is frustrating.

A crucial challenge is the mix of customer orders competing for the same resources, leading to changing priorities and poor customer service. To overcome these obstacles, accurate and properly structured data is essential.

The system causes inventory shortages, late shipments, production delays and the list goes on. You can see in your head how it should be done but you are stuck with what you got and it is frustrating.

A crucial challenge is the mix of customer orders competing for the same resources, leading to changing priorities and poor customer service. To overcome these obstacles, accurate and properly structured data is essential.

Imagine the Future of faster production

|

Imagine what your financial picture would look like if you could build your products in half the time you do today. You could double your sales volume without significant capital expense. In today's fast-paced business environment, speed is of the essence. Building a product quickly can mean the difference between success and failure with your customers. With shorter production cycles, you can be more responsive to customer needs to increase orders, deliveries, loyalty and profits.

The key to making this happen is simply viewing your business from a different angle. No need to tear everything down and rebuild because frankly, you don't have the time. To start you would build a simple data model of your operation from receiving to shipping so that you could connect all the dots. |

Build Products Twice as Fast with MonitorZ

|

Now that we have all the dots we are going to accelerate their velocity from the beginning of the maze to the finish line. How do we do that?

To speed up your production process, we have an innovative solution inspired by our collaboration with the Ford Motor Company's F150 program. We designed and built software that reduced time for suppliers to deliver the 30,000+ parts to build an F150 every 48 seconds. We will use what we learned and apply that knowledge to your production process and install simple mobile apps to track the dots we modeled. |

Estimate the Impact to Your Bottom Line

Let's crunch the numbers and see the potential impact on your operation. By cutting your production time in half, you can significantly reduce direct labor and overall operating costs. Take the guesswork out of your decision-making and make data-driven choices with confidence.

Simply enter your summary financial data into the fields below and you will see the impact to your finances. If you are producing various products use an average for your unit Production for the period. The period can be a month, quarter, year or whatever time span you want to compare.

*Please note that this is a static calculator and cannot retain data if you want a copy you must capture a screen shot

2X Impact Calculator

| Period 1 | Period 2 | |

|---|---|---|

| Sales | ||

| Cost of Goods Sold | ||

| Direct Labor | ||

| Gross Margin | ||

| S G & Admin | ||

| Net Profit | ||

| Unit Production | ||

| Unit Sale | ||

| Unit Direct Costs | ||

| Unit Burden Costs | ||

| Unit Total Cost | ||

| Unit Net |

When 2X is achieved, we can now see that each unit produced for the period only carries half the direct labor and burden as it did before. Your Gross Margin increases from the reduction of 50% of the Direct Labor and your Net Profit accumulates that and the 50% decrease in S G & A. To be fair, the sales potion of the S G & A may be higher if there are fixed sales costs per unit. This gives you the weapon to deliver faster and lower prices to beat your competition.

Upon seeing the results ask yourself, "How can I not take the initiative to build in half the time?"

Impossible? Think again. If Ford can put 30,000+ parts together in 48 seconds, it's possible you can make a 2X improvement.

Upon seeing the results ask yourself, "How can I not take the initiative to build in half the time?"

Impossible? Think again. If Ford can put 30,000+ parts together in 48 seconds, it's possible you can make a 2X improvement.

|

Ask yourself these important questions. |

|

|

How many prospects and customers last period were lost to long lead time? |

How many were lost on price? |

|

Can you afford to keep losing this revenue? |

How many non value added people do you pay to fiddle around with computers and spreadsheets? |

Why Accurate Data is Critical for Manufacturing Success

Imagine trying to keep a patient healthy without accurate data on their vital signs. Your manufacturing process is no different. Without real-time data from the shop floor, it's impossible to ensure the health of your business. Most ERP systems are designed for the office, not the factory floor, leaving you with incomplete information and causing chaos. MonitorZ was built to eliminate this problem. By collecting data directly from the manufacturing work centers, MonitorZ ensures that you always have the accurate data you need to make informed decisions and drive profits.

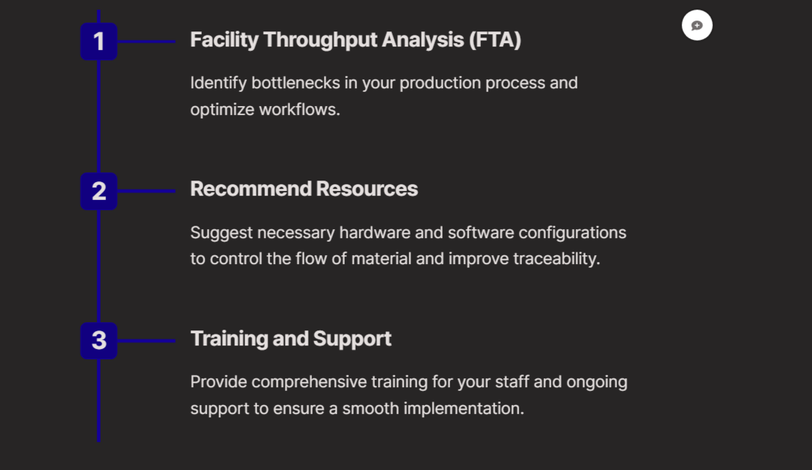

Our Comprehensive Plan

Implementing MonitorZ

With our experience and expertise, we will lead the way and conduct a Factory Throughput Analysis (FTA) that connects all the dots in your manufacturing processes using MonitorZ software. We will optimize material flow, track work orders using QR codes, and provide real-time visibility of your operations. Our software and philosophy are focused on increasing your capacity, sales, and customer success. With clear deliverables, ongoing support, and a new way forward, together we can achieve exceptional results.

Your Path to Success

Don't let Traditional ERP hold you back from improving your manufacturing operations MonitorZ offers a different approach with affordable monthly payments and a focus on long-term business viability. For just $1,850 per month for 24 months, you can have a successful and timely implementation of Object Velocity 2X. Experience the joy of a well-optimized manufacturing process without the need for excessive upfront payments. Contact us now and we will put you on the path to success.